- Open 7.30 AM - 9.30 PM

- (616) 901-6629 Serving all of the U.S.A.

PROVEN METHOD

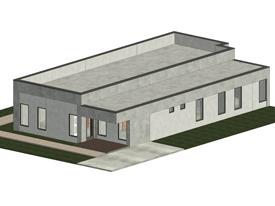

With many projects being debuted in the US and around the world, many are starting to see the potential of 3D printing in large scale. The many uses of this technology, from homes to furniture have begun to captivate people from all over the world. While our parent company is focused on 3D homes and condos, we decided to branch out into the dynamic home building community.

HOW IT WORKS

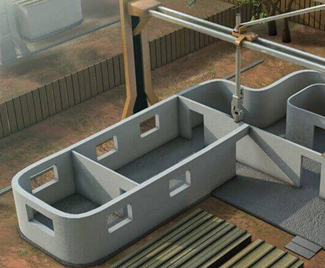

Most people are familiar with 3D printing at this point, but there are many that are blown away when it is used in this capacity. We use a gantry system that is similar to most small 3D printers. The process start to finish looks something like this:

1. Contact I Print Houses with or without prints.

2. Coordinate design build plan.

3. We have engineers on board, or bring your own.

4. Have site excavated, and slab poured.

5. We will deliver, set up, and print the walls using our 3D printer.

6. Depending on customer needs, we will install doors and roofs as well.

7. If necessary, after print has cured, we will pour the walls solid with the mix needed for the job.

8. Any extras like finishing the exterior walls with stucco, stone etc we can also handle.

Our STORY

" I Print Houses is a new player in the home building industry. We are not the first to offer this service in the home building industry but are very committed to be one of the best. Our parent company Kala Nea Construction specializes in homes and apartments, but with so much action in the home building industry, we were compelled to branch out. We hope you will consider us for your next home building project.”

OUR SERVICES

Simply put, 3D printing has the potential to upend construction in terms of speed, cost-efficiency, and productivity. That’s not empty hyperbole, either – professional, high-profile companies that have tried the technology agree.

3D vs CONVENTIONAL PROJECTS

3D concrete printing for construction has advanced rapidly over the past five years, with innovation in robotics, material science, and software, according to experts in the industry.

3D PRINT CONSTRUCTION

DURATION : 1 WEEK

CONVENTIONAL

CONSTRUCTION

DURATION : 6 MONTH

CONVENTIONAL

CONSTRUCTION

DURATION : 6 MONTH

CONSTRUCTION

DURATION : 6 MONTH

PROJECTS

CLIENTS SAY

Eliminating the need for casting concrete into molds or framework, 3DCP is a cost-effective building method. The curing time of such concrete can be as low as three days, and complete structures can be constructed within hours; making it a relatively quicker and cheaper alternative to conventional construction methods.

3D concrete printing uses extremely large-scale 3D printers, often measuring several meters in height and length to extrude a concrete from a nozzle. These machines generally come either as gantry or robotic arm systems.

Anonymous

CEO,Future Home Development Solutions

As for labor costs, they drop down basically to the daily wages of at most two or three operators. And that too is for a much shorter length of time as the 3D printed house would be ready for finishing and furnishing in days instead of months.

Anonymous

Construction Management

Whatever the printer’s configuration, practically all of them continuously extrude a dough-like concrete material that’s laid down in layers to create the desired building element.

Anonymous

Downtown Development Firm

REQUEST A QUOTE

Integrity and commitment that will stand the test of time. With I Print Houses you will get a beautiful energy efficient, climate controlled, strong building. The future is now and your dreams become a reality

Simply send us an email, give us your name and the best way to contact you and we will reply soon”.

> info@iprinthouses.com

Home Design Contest

Michigan Township of Flint. This is a unique chance for architectural students to showcase their creativity and contribute to developing sustainable and affordable housing solutions.

The winner of the competition will receive a prize of $500 and the opportunity to see their design incorporated into our 3D-printed housing project.

> www.iprint3dhouses.com

![]()

Follow Us On Facebook And Stay Up To Date On Our Latest Projects